Last edit: 30/01/2025

Trapped keys are devices used to ensure safe access to potentially live or dangerous plant or equipment in an industrial setting.

A trapped key interlocking system relies upon the transer of key(s) between a key-operated switch and an access lock.

Typically, in trapped key interlocking system, the access lock and the output system are physically separated and functionally linked by the transfer of the key.

These systems shall ensure a sequence of operation for equipment to ensure the intended risk reduction.

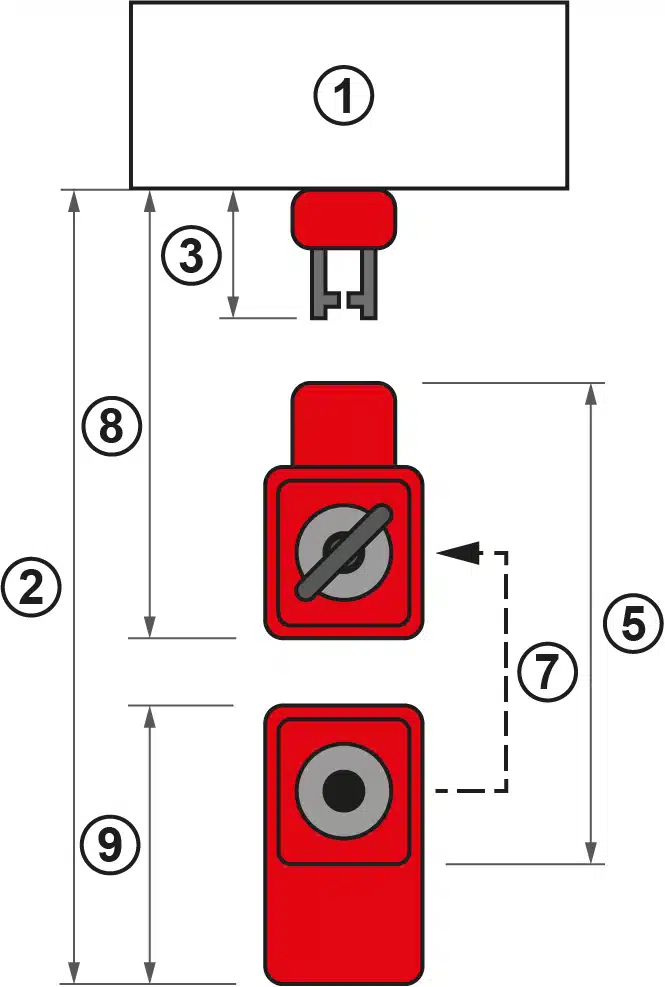

Key

1. movable guard

3. actuator

5. actuating system

6. output system

7. intermediate key transfer

8. Type 5 interlocking device (access lock)

9. Type 5 interlocking device (key operated switch)

10. trapped key interlocking system

Other interesting requirements regarding Trapped Keys in the Annex K are:

Key coding: Key coding shall prevent two or more type 5 devices of different safety functions on the same location unintentionally sharing an identical key as this can result in a hazard. Please notice that Type 5 interlocking devices and the corresponding keys are typically marked to avoid confusion.

Key retention. In order to prevent the key from being easily removed from the Type 5 interlocking device in the trapped position it shall not be possible to remove the key out of the Type 5 interlocking device with a force less than 250 N.

All of the parts that are intended for blocking the key, including the key itself, shall be able to withstand a torque of at least 5 Nm applied to the key.

Furthermore, at torque values greater than 5 Nm, it shall be ensured that the key does not shear out of the device resulting in a loss of the safety function (e.g.., through design features such as predetermined breaking points).

Reproduction of keys. Keys for Type 5 interlocking devices shall be designed in a way that they are not easily reproducible (for example with hand tools or a locksmith), other than by the original device manufacturer.