Last edit: 04/09/2023

People can get an Electric Shock due to two types of faults:

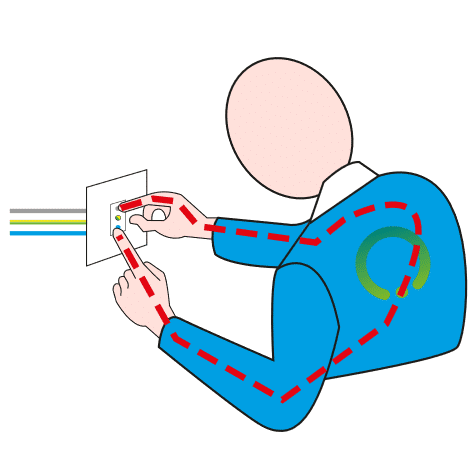

- Direct Contact: electric contact of persons or animals with live parts. In other words, I am subject to a direct contact if I touch a conductor. Protection against direct contacts is called Basic Protection.

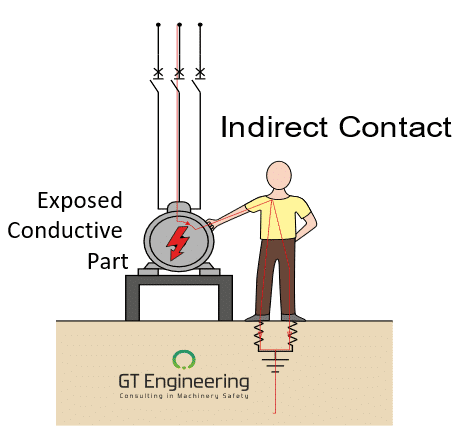

- Indirect Contacts: electric contact of persons or animals with exposedconductive-parts which have become live under fault conditions. I am subject to an indirect contact when I touch a metallic part that can become live due to a single fault. Protection against direct contacts is called Fault Protection.

Here are the key definitions:

[IEC 61140] 3.1.1 Basic Protection. Protection against electric shock under fault-free conditions.

[IEC 61140] 3.1.2 Fault Protection. Protection against electric shock under single fault conditions.

[IEC 61140] 3.1.4 Single Fault Condition. Condition in which one means for protection against electric shock is defective or one fault is present which could cause a hazard.

It is also important to distinguish between two important terms:

[IEC 61140] 3.17.5 Earthing (grounding in USA and Canada) conductor: conductor which provides a conductive path, or part of the conductive path, between a given point in a system or in an installation or in equipment and an earth electrode. Earthing means connecting to the “dirty ground”.

[IEC 61140] 3.16 Equipotential Bonding. provision of electric connections between conductive parts intended to achieve equipotentiality. Bonding means to connect two metallic parts.

And finally the two most important terms in Electrical Safety:

[IEC 61140] 3.6 Exposed-conductive-part. Conductive part of equipment, which can be touched and which is not normally live, but which can become live when basic insulation fails.

[IEC 61140] 3.7 Extraneous-conductive-part. Conductive part not forming part of the electrical installation and liable to introduce an electric potential, generally the electric potential of a local earth.