Last edit: 26/06/2023

6.1.2 Light beams devices

Light beams devices may provide one or more beams.

They require careful positioning to ensure they are effective because light beam devices have no specified detection capability but only detect interruption of the beams.

Each beam shall be able to detect an object of 120 mm diameter placed at the centre of the beam axis.

The positioning and characteristics of each beam shall take into account the possibility of:

– Encroachment between, over or under the beams

– Undetected penetration

– Crawling under, climbing through or jumping over

6.1.3 Optical Barriers.

The upper and lower beam heights of the optical barrier must be such that people are prevented from entering the hazardous area by passing over or under the detection area. The heights are specified in ISO 13855:2010.

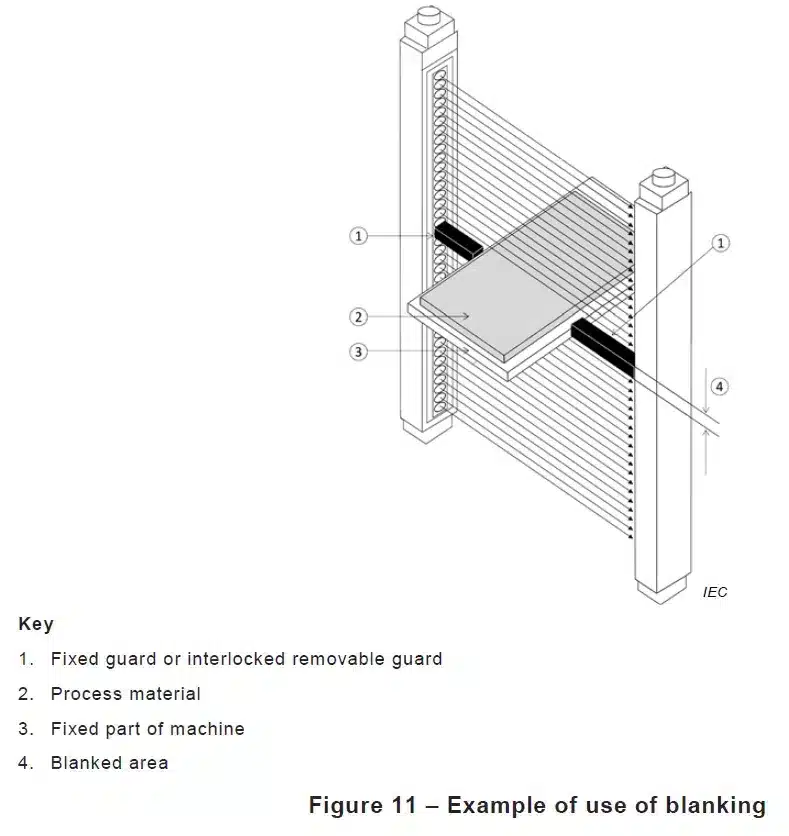

6.1.3.3 Blanking

The blanking function can be fixed or floating. Floating blanking is a technique in which the covered area of the detection zone follows the position of the moving object during operation.

It cannot always be assured that the covered area is completely obstructed by mechanical means. In such cases, the size of the opening in the detection zone determines the minimum distance between the AOPD and the hazardous zone.

The blanking function should not be available except when necessary for machine operations. The areas covered or the number of beams covered should not be greater than necessary for proper machine operation.

If, for a particular application, it is necessary to activate the blanking function for only part of the operating cycle, the blanking function must be started and ended automatically