Last edit: 13/10/2023

The doubt: in order to CE mark an Industrial Control Panel, shall I follow the prescriptions given by IEC 61439-1?

Considerations

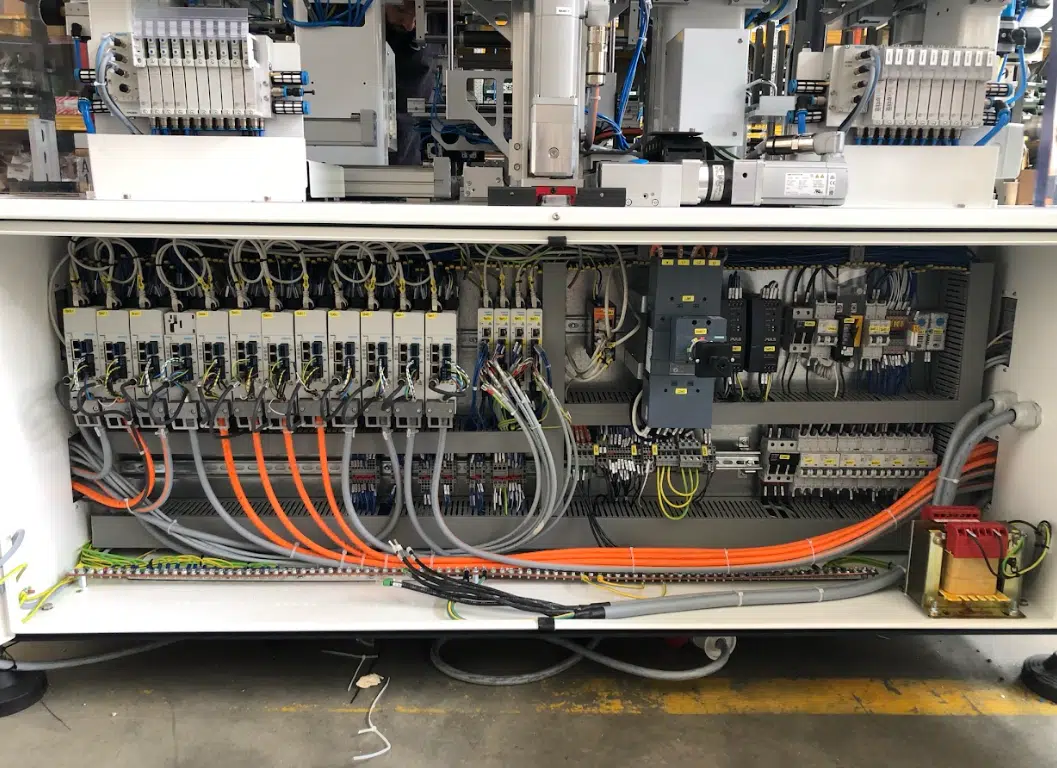

Consideration 1: The Electrical Equipment of Machinery must be engineered and built according to IEC 60204-1.

Inside the standard we find the following language:

[IEC 60204-1: 2016] 4.2.2 Switchgear – In addition to the requirements of IEC 60204-1, depending upon the machine, its intended use and its electrical equipment, the designer may select parts of the electrical equipment of the machine that are in compliance with relevant parts of the IEC 61439 series (see also Annex F).

It is clear that IEC 61439 series is not mandatory for Industrial Control Panels but it is a useful standard to refer to, for example in case the Panel has bus bars.

Consideration 2: The issue is the language contained in IEC 61439-1.

[IEC 61439-1: 2012] Part 1: General rules – 1 Scope

[…] This standard applies to low-voltage switchgear and controlgear assemblies (ASSEMBLIES) only when required by the relevant ASSEMBLY standard as follows:

[…] ASSEMBLIES designed for electrical equipment of machines provided that the other relevant specific requirements are complied with.

NOTE 3 Supplementary requirements for ASSEMBLIES forming part of a machine are covered by the IEC 60204 series.

That statement creates confusion, since it can be interpreted that the Machinery manufacturer has to apply also IEC 61439-2 in order to be able to CE mark its control panel and consequently, its machinery.

Consideration 3: True that IEC 60204-1 is not a panel standard but a standard for the whole Electrical Equipment of Machinery. True as well that IEC 61439-2 is the product standard for Distribution panels. However, IEC 61439-1 requires tests which are incompatible with an Industrial Control Panel, like the Short Circuit Test.

If you build a Distribution panel, you do not do any Short Circuit Test since the Manufacturer of the “Panel System” (ABB or SIEMENS or SCHNEIDER, or RITTAL or…etc) has done it for you years ago. But if you use the same “metal structure” to build a Control Panel for machinery, you cannot use the results of that verification and you should test your panel behaviour under a real a short circuit, verify that it passes the test and than rebuilt a “twin panel” since the one under test was damaged.

That does not make sense! UL 508A has the excellent “SUPPLEMENT SB – SHORT CIRCUIT CURRENT RATINGS FOR INDUSTRIAL CONTROL PANELS” that provides a methodology how to calculate the SCCR of an industrial Control Panel and it does not require any short circuit test!

Consideration 4: Since many years, among the experts working in this field and who participate to various Technical Committees, it is accepted the fact that IEC 61439-1 is a good source of prescriptions for the Panel Manufacturer, but its full application is not mandatory. Several European Standardisation Organisations like CEI in Italy or DKE in Germany, have already taken officially that position. Formally we still have the sentence in IEC 61439-1 that states the standard is applicable to “ASSEMBLIES designed for electrical equipment of machines”.

That language is now fully removed in IEC 61439-1: 2020 and IEC 61439-2: 2020. Once those two standards will be harmonised with their publication int eh OJEU, the issue and the confusion that it generates will be finally completely over.

Conclusions

If you are a panel manufacturer you need to indicate the Short Circuit Current Rating of your product. That value must be higher that the Perspective Short Circuit Current the panel is subject. That means the maximum short circuit current that can be generated at the point where your panel is connected to the network.

Therefore, if you need to build a panel with and SCCR of 25 kA, pay attention that it is not enough to have the Main Disconnecting Device with an Interrupting Rating equal or higher than 25 kA.

Once you are confident the panel you engineered has indeed 25 kA, just declare it on the Panel Plate and do not worry about the short circuit test! That is only a “normative issue” and not a Real Safety problem!