Last edit: 03/06/2024

EN ISO 13577 is the series of standards, at international level, that give prescriptions on how to design a safe Industrial Furnace.

In Europe, so far, we followed EN 746 series, whose principles are derived from the ISO standard. Latest Edition of EN 746-2 is dated 2010. Latest edition of EN ISO 13577-4 is dated 2014, A new edition was published in July 2022. GT Engineering has participated in its development, giving a significant contribution to the Functional Safety Part. A new edition of EN ISO 13577-2 will be published in 2023. The objective is that the new EN ISO 13577-4, together with EN ISO 13577-2 will replace EN 746-2 in due course.

EN ISO 13577 consists of the following parts, under the general title Industrial furnaces and associated processing equipment — Safety:

- Part 1: General requirements

- Part 2: Combustion and fuel handling systems

- Part 3: Generation and use of protective and reactive atmosphere gases

- Part 4: Protective systems

The acronym used in the standard to indicate industrial furnaces and associated processing equipment was IThE (EN 746-2) and it is now TPE.

What are the main changes compared to the 2014 edition of EN ISO 13577-4?

- It was made clear that the EN ISO 13577 series is not applicable to Petrochemical furnaces. EN 7462 mentions, as examples of IThE (Annex A), several types of furnaces in the chemical/petrochemical industry. In the new edition of EN ISO 13577-2 it is stated:

[EN ISO 13577-4: 2022] 1 Scope

[…] This document is not applicable to blast furnaces, converters (in steel plants), boilers, fired heaters (including reformer furnaces) in the petrochemical and chemical industries.

– EN 746-2 allows the use of instrumentation, non SIL certified, to take case of the furnace Safety. That is detailed in chapter 5.7 of EN 746-2 and it is derived from Method A of EN ISO 13577-4. The approach is kept in Iso 13577-4: 2022 edition, as well. In case some of the components, SIL certified, are used for the Furnace Safety, that is known as “Method B” or Method “C”. Since the differences between the two method were small, in the new edition of EN ISO 13577-4, Method B and Method C were combined in one called Method BC. That approach is used every time either the input subsystem, or the logic or the output subsystems are SIL certified.

The principles of the three methods (A, BC, or D) are hereafter summarised:

– Method A: wired system, all devices comply with relevant product standards; SIL- / PL-calculation is not required;

– Method BC: combination of devices meeting relevant product standards with devices for which no relevant product standard exits. SIL- / PL-calculation for the subsystems with no product standard is required;

– Method D: full requirement in accordance with the IEC 61508:2010 series, the IEC 61511:2016 series, IEC 62061:2021, or ISO 13849-1. SIL / PL calculation is mandatory for each safety function.

– Here is now a better alignment with ISO 13849-1 and IEC 62061. Therefore, Annex E has been significantly modified to reflect the approach by Subsystems and Subfunctions, now widely established in both ISO 13849-1 and IEC 62061. The first part of Annex E shows several examples of how to implement an input subsystem with either Method A or Method BC. The same approach is shown for the Logic and for the Output Subsystem.

On that basis, the examples present in the 2014 edition of EN ISO 13577-4 were redrawn and may were made new, highlighting the new approach by subfunctions.

– Annex B and Annex F were merged and a clearer language with better examples are now present in the revised Annex.

The Annex makes it clear that the furnace electrical installation must comply with IEC 60204-1:2016. It describes how to wire the protective system so as not to reduce the level of safety and it applies to the wiring within the logic solver, and the wiring between the logic solver and the devices that directly or indirectly control the final elements. Moreover, it applies to the field wiring like sensors, interlocks, actuators, final elements, flame detector, igniter, etc.

To maintain the level of safety of the wired protective system, techniques shall be applied to avoid or prevent the introduction of systematic faults during design and development and to apply design features (e.g. selfchecking, redundancy) to control both random and systematic faults during operation.

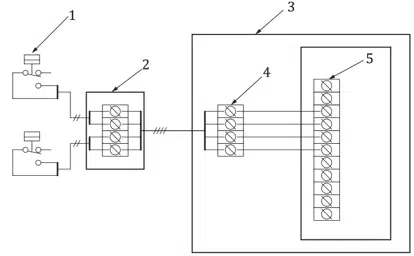

Picture hereafter shows how to connect two pressure switches to the control panel.