Last edit: 10/08/2023

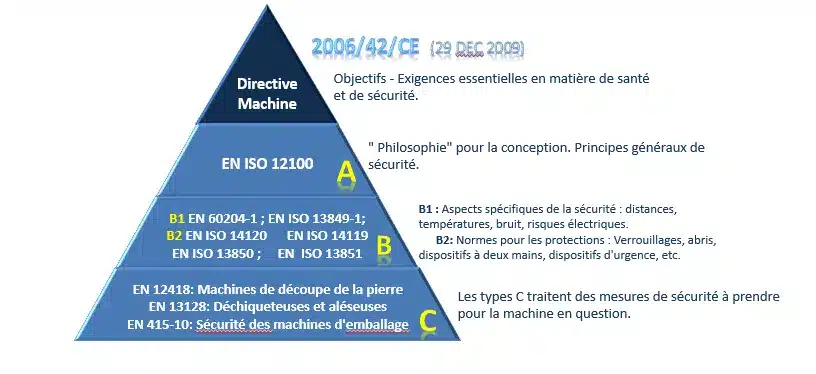

Harmonized standards play an important role in the EU Legislation for the CE Marking of Machineries. ISO classifies the 800+ International technical standards harmonised to the machinery directive in 3 categories:

- type-A standards (basic safety standards) giving basic concepts, principles for design, and general aspects that can be applied to machinery;

- type-B standards (generic safety standards) dealing with one safety aspect or one type of safeguard that can be used across a wide range of machinery;

- type-C standards (machine safety standards) dealing with detailed safety requirements for a particular machine or group of machines.

At the side you can download the latest list of Harmonised Standards to the Machinery Directive.

TYPE-A STANDARD (ISO 12100)

ISO 12100 specifies the principle strategy for safety of machinery. Risk assessment and adequate risk reduction by an iterative three-step method are the imperative measures to design a machine to achieve a level of tolerable risk.

To implement risk assessment and risk reduction, the following actions should be taken by the designer in the order given:

- determine the limits of the machinery, which includes the intended use and any reasonably foreseeable misuse thereof;

- identify the hazards and associated hazardous situations;

- estimate the risk for each identified hazard and hazardous situation;

- evaluate the risk and decision whether a risk reduction is needed or not;

- eliminate the hazard or reduction of the risk associated with the hazard by means of protective measures/risk reduction measures.

Actions a) to d) are related to risk assessment and action e) to risk reduction.

Risk assessment is a series of logical steps to enable, in a systematic way, the identification of hazards as well as the estimation and evaluation of the risks associated with machinery. As a result of the risk assessment, the hazards requiring risk reduction are determined. Iteration of the process of risk assessment can be necessary to eliminate newly generated hazards as far as reasonably practicable or to adequately reduce associated risks by the implementation of protective measures/risk reduction measures in order to achieve tolerable risk.

Protective measures/risk reduction measures are the combination of the measures implemented by the designer and the user. Measures which can be incorporated at the design stage are preferable to those implemented by the user and usually prove more effective.

TYPE-B STANDARD

According to ISO 12100, type-B standards deal either with one safety aspect (type-B1 standard) or one type of safeguard that can be used across a wide range of machinery (type-B2 standard). Type-B standards are intended to support the principle strategy from ISO 12100 in order to:

- help determine if a hazard exists, for example, ISO 13857; and

- provide concrete information/measures to perform risk reduction, for example, ISO 14120.

Type-B1 standards deal with particular safety aspects (for example, safety distances, surface temperature, noise) and define by data and/or methodology how these can be addressed. Type-B1 standards can be used directly by the designer/manufacturer or by reference in type C standards, including, where relevant, means of verification.

Type-B2 standards provide the performance requirements for the design and construction of particular safeguards (for example, two-hand control devices, interlocking devices, pressure-sensitive protective devices, guards). Type-B2 standards can be applied either directly by the designer/manufacturer or by reference in type-C standards. Together with those performance requirements, type-B2 standards specify, where relevant, means of verification.

TYPE-C STANDARDS

According to ISO 12100, type-C standards provide detailed safety requirements for particular machinery or group of machinery. They are machine specific and their scope is determining the limits of the machinery and the significant hazards covered.

Type-C standards are written by a team of technical experts (in particular, from machine manufacturers and representatives from health and safety bodies) knowledgeable in the machine design (intended use), the practical use of the machine, the accident history and health records, available risk reduction techniques, and the legal frameworks in which the machine is intended to be used (placed on the market).

Type-C standards deal with all the significant hazards of a particular machine by:

- referencing relevant and applicable type-B standards;

- referencing other standards (e.g. a type-C standard), where such significant hazards are adequately dealt with;

- specifying safety requirements in the standard, when reference to other standards is not possible or not sufficient and where risk assessment and priorities show this is required; and

- dealing as far as possible with objectives rather than design prescriptive details to minimize restrictions on design.