Last edit: 01/08/2023

Introduction

Sound can be described as any pressure variation that human can hear.

The exposure to intense sounds for long period of time can harm the personal health of the operators: it becomes necessary to intervene in the situations where sound values exceed limit values imposed from health and security standards.

In the “Machinery Safety” it’s reported:

Operators should not be exposed to workplace noise likely to cause noise-induced

hearing loss according to ISO 1999:2013 or a national equivalent standard;

Ambient noise should not interfere with task performance;

The Decibels

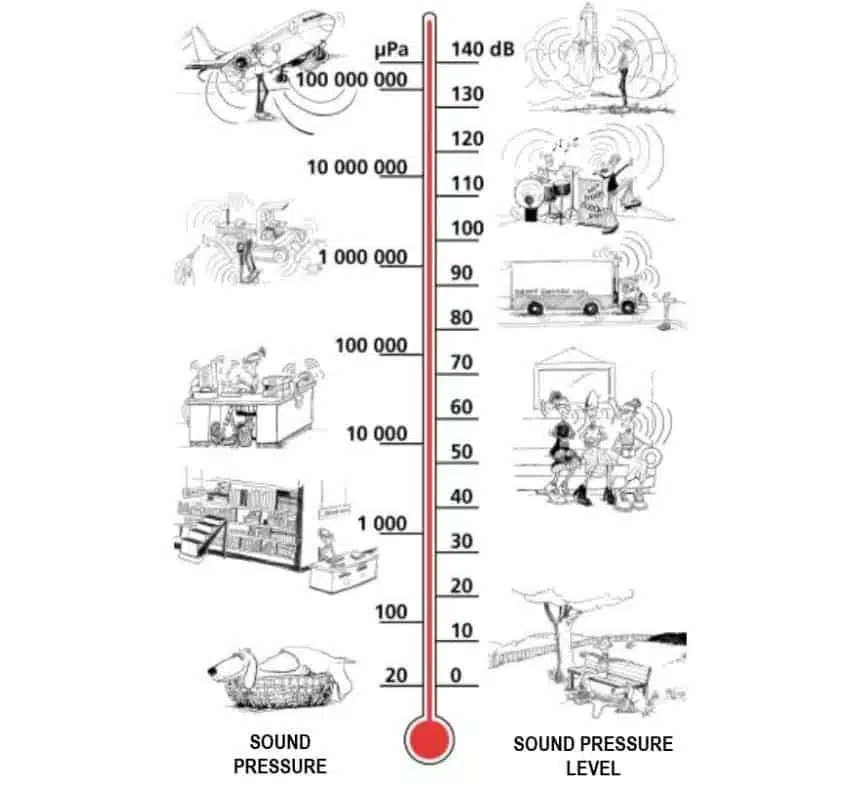

Compared to the static air pressure (105 Pa), the audible sound pressure variations are very small, ranging from about 20 µPa (20 ×10-6 Pa) to 100 Pa.

20 µPa corresponds to the average person’s threshold of a hearing. It is therefore called the threshold of hearing.

A sound pressure of approximately 100 Pa is so loud that it causes pain and is therefore called the threshold of pain. The ratio between these two extremes is more than a million to one.

A direct application of linear scales (in Pa) to the measurement of sound pressure leads to large and unwieldy numbers. And, as the ear responds logarithmically rather than linearly to stimuli, it is more practical to express acoustic parameters as a logarithmic ratio of the measured value to a reference value. This logarithmic ratio is called a decibel or dB.

So, the linear scale with its large numbers is converted into a manageable scale from 0 dB at the threshold of hearing (20 µPa) to 130 dB at the threshold of pain (~100 Pa).

Types of Noise

When measuring noise, we need to know the type of noise so that we can choose the parameters to measure, the equipment to use, and the duration of the measurement.

In industrial applications we can distinguish four different types of noise:

- CONTINUOUS NOISE: Continuous noise is produced by machinery that operates without interruption in the same mode, for example, compressors, pumps and processing equipment.

- INTERMITTED NOISE: When machinery operates in cycles the noise level increases and decreases rapidly. For each cycle of a machinery noise source, the noise level can be measured just as for continuous noise.

- IMPULSIVE NOISE: The noise from impacts or explosions, for example the ones produced by pile drivers or mechanical presses, is called impulsive noise. It is brief and abrupt, and its startling effect causes greater annoyance than would be expected from a simple measurement of sound pressure level.

- LOW FREQUENCY NOISE: Noise of this kind is typical for large diesel engines since the noise is hard to muffle and spreads easily in all directions. Low frequency noise is more annoying than the one measured as the A-weighted sound pressure level

Sound Propagation

The level of noise gets influenced from a lot of factors and the measurement results can vary by 10 decibels for the same noise source. To explain how this variation comes about, we need to consider how the noise is emitted from the source, how it travels through the air, and how it arrives at the receiver.

The most important factors affecting noise propagation are:

- Type of source

- Distance from source

- Atmospheric absorption

- Wind

- Temperature and temperature gradient

- Obstacles such as barriers or buildings

- Ground absorption

- Reflections

- Humidity

To arrive at a representative result for measurement or calculation, these factors must be taken into account. Also, from standards requests and to have a more precise measure, it’s request the calibration of the phonometer before making measures on the machinery.

GT Engineering has the necessary tools to correctly execute measure of the sound and give precise data of your machinery’s sound emissions.

Sound Pressure, Sound Power and Sound Intensity

Sound is characterized from different magnitudes. Those that interest Machinery Directive are:

- Sound Pressure: it’s what human can hear. This magnitude, converted on the scale of decibels, takes the name of “Sound Pressure Level”. The sound pressure level it’s a measure of the effect caused by the energy of one or more acoustic source and it’s influenced by the distant at which we are from the acoustic source and from the environment. In the Machinery Directive, sound pressure level it’s called “emission sound pressure level”. This represents the sound pressure level at which an operator is exposed, in a free field above a reflective plane.

The sound pressure is influenced by the environment: the same noise source has different values of sound pressure in function of the distance from the source or if in presence of reflective walls.

- Sound Power: it’s the acoustic power (W) irradiated from an acoustic source; this magnitude, converted in the scale of decibels, takes the name of “sound power level”. This power is independent from the environment condition and it characterizes in a precise way a sound source. On the other hand, while the measure of sound pressure is relatively simple (you only need a phonometer), the measure of the sound power needs a more articulated procedure.

- Sound Intensity: the standard ISO 9614 defines the concept of sound intensity:

it’s the instantaneous flow of sound energy per unit of area and per unit time in the direction of the local instantaneous acoustic particle velocity.

This is a vectoral quantity which is equal to the product of the instantaneous sound pressure at a point and the associated particle velocity:

Like it can be seen from the definition reported by the standard, sound intensity is strictly bound to sound energy and, consequently, to the sound power too. In fact, with appropriate tools that can measure sound intensity, it is possible to go back to the sound power of the interested source.

This method of determination of the sound power level is comparable to the thermal imager concept: a thermal imager gives back an image where hot zone and cold zone are clearly distinguished. Using the measuring methods of sound intensity you have a precise image of the sound source in exam that distinguishes its characteristic in every interested point.

In the “Machinery Directive 2006/42/CE” it’s reported:

Each instruction manual must contain, where applicable, at least the following information:

…u) the following information on airborne noise emissions:

— the peak C-weighted instantaneous sound pressure value at workstations, where this exceeds 63 Pa (130 dB in relation to 20 µPa),

— the A-weighted sound power level emitted by the machinery, where the A-weighted emissions sound pressure level at workstations exceeds 80 dB(A).

Reference Standards

The reference standards for the correct measurement of sound emission are:

- ISO/TS 7849: “Determination of airborne sound power levels emitted by machinery using vibrations measurements”

- ISO 3740: “Determination of sound power levels of noise sources – Guidelines for the use of basic standards”

- ISO 3741: “Determination of sound power levels and source energy levels of noise sources using sound pressure – Precision methods for reverberation test rooms”

- ISO 3743: “Determination of sound power levels and source energy levels of noise sources using sound pressure – Engineering methods for small movable sources in reverberant fields”

- ISO 3744: “Determination of sound power levels and source energy levels of noise sources using sound pressure – Engineering methods for an essentially free field over a reflecting plane”

- ISO 3745: “Determination of sound power levels and source energy levels of noise sources using sound pressure – Precision methods for anechoic and semi-anechoic rooms”

- ISO 3746: “Determination of sound power levels and source energy levels of noise sources using sound pressure – Survey method using an enveloping measurements surface over a reflecting plane”

- ISO 3747: “Determination of sound power levels and source energy levels of noise sources using sound pressure – Engineering/survey methods for use in situ in a reverberant environment”

- ISO 9614: “Determination of sound power levels of noise sources using sound intensity”

There are a lot of factors that affect the selection of the standard to use to determinate the Sound Power Level.

GT Engineering does sound emissions analysis of machinery or production lines.