Last edit: 03/08/2023

THE DOUBT

In the design of the electrical system, how can I distinguish which of the metal parts is an exposed conductive part? Is bonding all metal parts a valid safety measure, or can it even be counterproductive?

CONSIDERATION

The difference between Exposed Conductive Parts and a Metal frame can be un unclear. For an exact definition of exposed conductive part we refer to IEC 61141:

[IEC 61141-3.6] "Exposed conductive part: conductive part of equipment, which can be touched, and which is not normally live, but which can become live when basic insulation fails."

How should metal frames in direct contact with an exposed conductive part be considered? Since they can become energised when the exposed conductive part itself is subject to a ground fault and becomes energise? Again, the standard clarifies the situation:

[IEC 61141-3.6- Note 1] " A conductive part of electrical equipment which can become alive only through contact with an exposed conductive part which has become live, is not considered to be an exposed conductive part itself."

For example, the frame of an electrical motor is an Exposed conductive part, while his metal basement is not an exposed conductive part, although, in the event of a ground fault, both can become energised.

Every exposed conductive part, in order to be adequately protected for indirect contact (Fault protection), have to be bonded. However, this fundamental rule is often misinterpreted; here are, for example, some incorrect statements regarding exposed conductive part and grounding:

- Anything that can become energised must be bonded.

- Metal parts that do not move must be grounded (if it doesn't move, than ground it).

- Grounding "discharges" the fault current to the ground.

- Grounding keeps the exposed conductive part at ground potential (zero), even in the event of a failure…. Very wrong!!!

Grounding has the task of creating a fault loop, which is monitored by magnetic protections or RCDs. It does not, therefore, discharge the current, nor does it bring the exposed conductive part to the potential of the ground: if that were the case, touching it during a ground fault would not bring any risk of electrocution, and there would be no need for circuit breakers.

Referring to those wrong statements, often every fixed metal part is bonded, even those not in contact with an exposed conductive part. This is a wrong and even dangerous practice: only exposed conductive parts must be grounded.

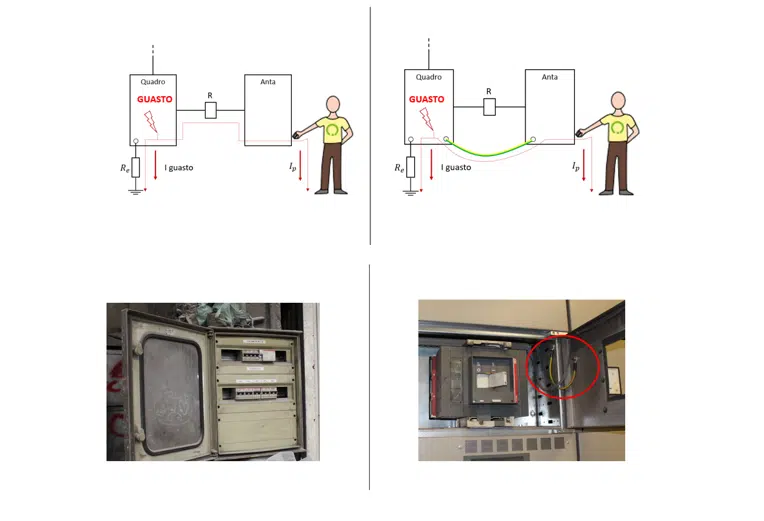

Let’s, for example, look at the two scenarios in the figure below.

A distribution panel (exposed conductive part) is correctly grounded; the metal door is not an exposed conductive part: a fault in the panel does not directly cause it to become live. The joint of the door constitutes an electric resistance that lowers the voltage of the door in case of fault. The addition of the ground connection actually bypasses this resistance, raising the contact voltage of the door to the value of the panel.

Similar settings are often applied to fixed shelters, metal doors, supports: these ground connections connect to the electrical ground circuit parts that are not normally included in it, increasing the risk in case of indirect contact. The red door of a panel room cannot become live, being far from any electrical equipment. If we ground it, when a ground fault occurs it will become live: in this case, grounding lowers the safety level of the plant.

CONCLUSION

Among the metal parts of the plant, only those which, due to a failure of the main insulation, become directly live should be considered exposed conductive parts. When those exposed conductive parts are identified, they all must grounded to prevent the risk of electrocution. If a conductive part is not an exposed conductive part, it should not be grounded: the connection to the ground circuit of these parts increases the risk in the event of indirect contact.