Last edit: 10/05/2023

Circuit breakers are meant to protect the circuit from overcurrents, which can be divided in two categories:

- overload, i.e. a current that settles in an electrically healthy circuit (for example, an electric motor that moves a shaft with defective or worn out bearings is forcibly slowed down and absorb more current).

- short circuit, i.e. a current produced by a negligible impedance failure between two parts of the circuit (examples are short circuit between phases, or short circuit between phase and neutral).

These two types of overcurrents have hugely different intensities, the overload type can be tolerated if temporary, while the short circuit, of much greater intensity, must be immediately interrupted; the circuit breaker allows you to manage both cases.TheHarmonized Standard for this type of switches are the EN 60898 (domestic installations) and the EN 60947-1 (general use, for applications under 1000 Vac or 1500 Vdc).

Circuit Breakers have double protection:

- Thermal protection: the current flows into a bi-metallic foil, the Joule effect generates a different thermal expansion on the two metals causing a curvature; n presence of overload, the heat generated increases and the steeper curvature triggers an anchor that interrupts the circuit.

- Magnetic protection: the current of the circuit flows in a coil; in presence of short circuit, the magnetic field generated by the coil moves an anchor that interrupts the circuit.

Both protections are present inside the switch and are simultaneously active in monitoring the circuit; there must therefore be a principle indicating when to activate one or the other.

MINIATURE CIRCUIT BREAKERS

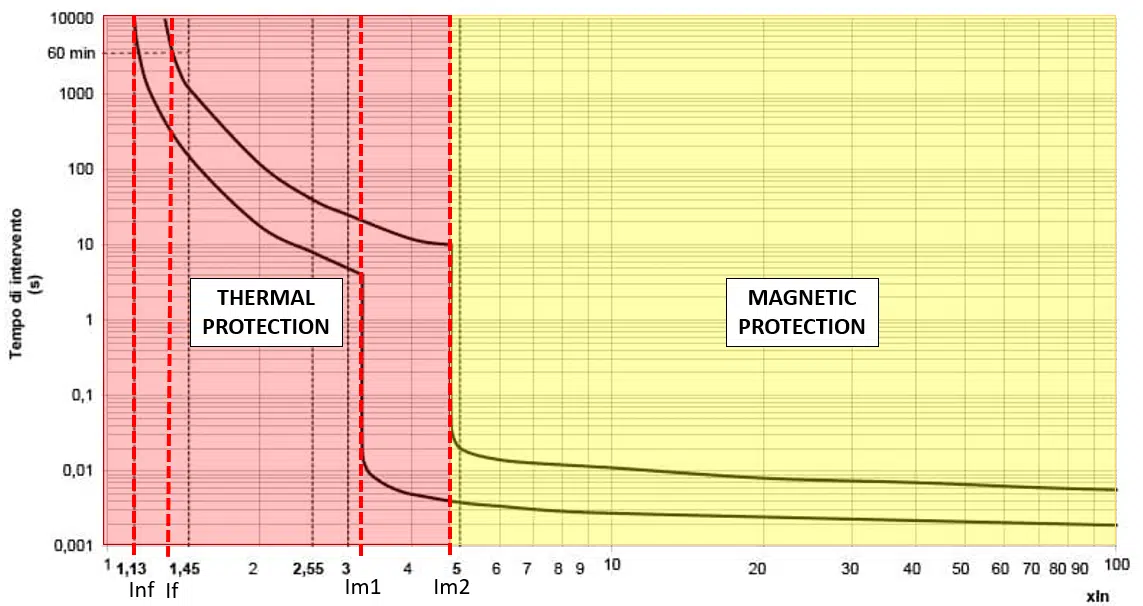

Generally, each protection is associated with different values of overcurrents. As the graphic shows, low value overcurrents generated by overload, are managed by thermal protection. The thermal protection does not activate instantly (time dipendent protection), but with a certain delay inversely proportional to the value of the overcurrent: in this way brief overcurrents, such as the starting currents of the motors, do not unnecessarily trigger the switch. We define Inf (non-functioning current, must be equal to 1,05 In acccording to EN 60947) as the maximum overcurrent value that does NOT trigger thermal protection, and If (functioning current, must be equal to 1,25 In acccording to EN 60947) the minimum overcurrent value that triggers thermal protection in conventional time (1 h).

Magnetic protection triggers for much intense overcurrents, typical of a short circuit: these currents are extremely dangerous, both for humans and for the system, and must therefore be interrupted quickly. Magnetic protection interrupts the current in tenths of a second, safeguarding the circuit. We define Im1 as the minimum overcurrent that can trigger magnetic protection and Im2 as the minimum current that DEFINITELY triggers magnetic protection to intervene.

This graph is actually not typical of all circuit breakers, but only of Miniature Circuit Breakers. MCBs are divided according to IEC 60898-1 into different categories depending on the magnetic protection activation threshold:

- Type B, with intervention threshold for short circuit between 3 and 5 times the nominal current (In) of the circuit (protecting loads that generate limited overload, such as lighting).

- Type C, with intervention threshold for short circuit between 5 and 10 times the nominal current (In) of the circuit (standard load protection).

- Type D, with intervention threshold for short circuit between 10 and 20 times the nominal current (In) of the circuit (protecting loads that generate high overloads, such as electric motors).

MOULDED CASE CIRCUIT BREAKERS – AIR CIRCUIT BREAKERS

In the industrial field, we may need a switch with a particular characteristic curve, which can be modified according to operating conditions; in this case, miniature circuit breakers are not fit for purpose. Moulded Case Circuit Breakers (MCCB) and Air Circuit Breakers (ACB), in addition to operating on current values higher than the modular ones, allow to calibrate the tripping settings of magnetic or thermal protections, if necessary. Although the terms "thermal" and "magnetic" are still used, these switches, having to manage high currents, do not rely on the physical mechanics already exposed but are based on eletronic control.

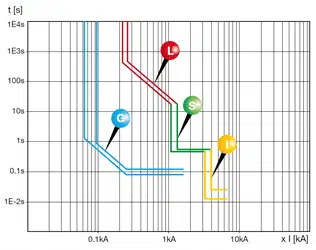

In low voltage MCCB, there are four different tripping settings:

- L- LONG TIME DELAY (thermal protection): time-dependent curve, is calibrated to values close to Ib (operating current).

- S- SHORT TIME DELAY (magnetic protection): it can also be time-dependent, it indicates the first activation of magnetic protection; the scheduled delay guarantees selectivity between the switches of the system.

- I- INSTANTANEOUS PICKUP (instantaneous magnetic protection): it allows the activation of magnetic protection in tenths of a second; it is calibrated to work close to the minimum expected short-circuit current.

- G- GROUND FAULT: takes care of the protection from ground fault, keeping the current vectors and their possible variations under control; for more information please refer to this link.

For remarkably high nominal currents, above 800 A, Air Circuit Breakers are used. ACBs, through electronic control, monitor the passage of current and, when necessary, open the circuit using air as dielectric to interrupt the electric arc. The big difference compared to MCCBs, in addition to the higher current managed, is the possibility of delaying the instantaneous magnetic protection up to 1 s, so as to guarantee the selectivity of the system

CONCLUSION

Circuit Breaker, acting through a double mechanism, guarantees protection from both overloads (using thermal protection) and short circuits (using magnetic protection); through their tripping settings, in some cases adjustable as needed, they can be adapted to the loads of the system and the expected overcurrents, so as to act promptly only when necessary.