Last edit: 01/07/2025

The doubt

What is the breaking capacity of a protective magnetotermical device or a fuse?

Consideration 1: the overload and the short-circuit

One of the problems related to the dangerousness of electrical current is the fact that cables and utilisers can catch on fire if traversed by a current bigger than the one predicted for its normal use.

The two phenomena which can cause the occurrence of these cases are the following:

Overload: In the electrical field, the overload is a condition in which a circuit or component is traversed by a current much bigger than is nominal current, but not at a level that can cause a short-circuit, generally in the condition wich the circuit is considered healty, wich is fault free. This excess of current, although it is not immediatly dangerous like a short-circuit, can lead to an overheating of the condutting cables and, in the long run, at the deterioration of the isolation and, potentially, cacth on fire. Legislative definition: the standard of referernce, IEC 60364-4-43, defines the overload as a condition in wich the current that goes along the conductive cable exceed is nominal reach (maximum bearable current), in a healty electrical circuit.

[IEC 60364-4-43: 2023] 430.3 Terms and definitions

430.3.5 Overload: operating conditions in an electrically undamaged circuit, which cause an overcurrent.

430.3.2 Overload current: overcurrent occurring in an electric circuit, which is not caused by a short-circuit or an earth fault.

This can appen when too many devices at high absorbtion rate get connnected at the same line or when a device gets used over its reccomended specifics.

[IEC 60364-4-43: 2023] 430.3 Terms and definitions

430.3.1 Overcurrent: electric current the value of which exceeds a specified limiting value.

Note 2 to entry: An overcurrent is an overload current or a short-circuit current.

Short-circuit: a sohrt-circuit is defined as a fault in an electrical circuit in wich two points with different potential( for example, phase and neutral conductor, or two phases) are connected with very low or no resistance, causing a sudden and noticeable increase in the electric current.

[IEC 60364-4-43: 2023] 430.3 Terms and definitions

430.3.4 short-circuit: accidental or intentional conductive path between two or more conductive parts forcing the electric potential differences between these conductive parts to be equal to or close to zero.

This increase of current, much bigger than the nominal current of the circuit, can lead to damages at the implant, overheating, fires o malfunctioning of the connected devices.

Difference between overload and short-circuit. It is important to distinguish between this two. The short-circuit it’s a fault in wich the current finds a path at very low resistivity, causing a flux of very elevated and potentially dangerous current.

The overload, instead, is a condition of overcurrent that occurs in a healty electrical circuit, even if potentially dangerous if persistent. To protect the circuit from the overload and from short-circuit automatic protections like magnetotermical protective devices or fuses are used, that open the electrical circuit when they detect those situations.

Consideration 2: The breaking capacity and its standards

Important for protections against short-circuit and their direct protection, its the breaking capacity of the protective device.

Breaking capacity: the breaking capacity is the maximum current that the component is capable of interrupting in a safe way, without damaging its self, in the occurence of a fault. In a simpler way it’s the capacity of a device to open a short-circuit when the current reaches a value that can be identified as a short-circuit, protecting the implant from eventual damaging.

[IEC 60947-2: 2024] 4.3.6.2 Rated short-circuit breaking capacities

4.3.6.2.1 General. The rated short-circuit breaking capacities of a circuit-breaker are the values of short-circuit breaking capacity assigned to that circuit-breaker by the manufacturer for the rated operational voltage, under specified conditions.

A rated short-circuit breaking capacity requires that the circuit-breaker shall be able to break any value of short-circuit current up to and including the value corresponding to the ratedcapacity at a power-frequency recovery voltage corresponding to the prescribed test voltage values […]

This breaking capacity, or short-circuit power is intended only in cases where the device is capable of extinguishing the electric arc generated at the extremities of the poles of the device, in order to avoid the protective device to catch on fire or explode.

Unfortunatelly , for an appassionate reader of this topic, a protection can have more than one, which are listed in the respective standards. The standards that regulate and define the breaking capacity are two:

- EN 60947-2: for industrial switch devices

- EN 60898-1: for civil switch devices

EN 60947-2: 2016. Low-voltage switchgear and controlgear – Part 2: Circuit-breakers

It defines two breaking capacities:

The Icu (extreme breaking capacity) defines as the maximun current that it is capable to open; it needs to satisfy the sequence OtCO, or respecting the procedures of opening and closing like reported in the text of the standard later reported:

[IEC 60947-2: 2016] 8.3.2.6.4.4 Test operations The following symbols are used for defining the sequence of operations:

- O represents a breaking operation.

- CO represents a making operation followed, after the appropriate opening time, by a breaking operation:

- t represents the time interval between two successive short-circuit operations which shall be as short as possible, allowing for the resetting time of the circuit-breaker (see 2.19), but not less than 3 min. The actual value of t shall be stated in the test report.

The maximum resetting time shall be 15 min or such longer time as may be stated by the manufacturer, but not exceeding 1 h, during which time the circuit-breaker shall not be displaced. Attempts to reclose the circuit-breaker during the resetting time shall be spaced by at least 1 min.

The maximum value of I2t (see 2.5.18 of IEC 60947-1:2007) during these tests may be recorded in the test report (see 7.2.1.2.4, item a)).,

After that it needs to be substituted.

[IEC 60947-2: 2016] 4.3.6.2.2 Rated ultimate short-circuit breaking capacity (Icu) The rated ultimate short-circuit breaking capacity of a circuit-breaker is the value of ultimate short-circuit breaking capacity (see 2.15.1) assigned to that circuit-breaker by the manufacturer for the corresponding rated operational voltage, under the conditions specified in 8.3.5. It is expressed as the value of the prospective breaking current, in kA (r.m.s. value of the a.c. component in the case of a.c.)

The Ics (service breaking capacity) defined as having to comply with the OtCOtCO sequence, or to respect the procedures of openig and blocking like how reported in the text of the standard later reported:

[IEC 60947-2: 2016] 8.3.2.6.4.4 Test operations The following symbols are used for defining the sequence of operations:

- O represents a breaking operation.

- CO represents a making operation followed, after the appropriate opening time, by a breaking operation:

- t represents the time interval between two successive short-circuit operations which shall be as short as possible, allowing for the resetting time of the circuit-breaker (see 2.19), but not less than 3 min. The actual value of t shall be stated in the test report.

The maximum resetting time shall be 15 min or such longer time as may be stated by the manufacturer, but not exceeding 1 h, during which time the circuit-breaker shall not be displaced. Attempts to reclose the circuit-breaker during the resetting time shall be spaced by at least 1 min.

The maximum value of I2t (see 2.5.18 of IEC 60947-1:2007) during these tests may be recorded in the test report (see 7.2.1.2.4, item a)).,

After that it needs to ensure the service ( it needs to be able to maintain the nominal current In).

[IEC 60947-2: 2016] 4.3.6.2.3 Rated service short-circuit breaking capacity (Ics) The rated service short-circuit breaking capacity of a circuit-breaker is the value of service short-circuit breaking capacity (see 2.15.2) assigned to that circuit-breaker by the manufacturer for the corresponding rated operational voltage, under the conditions specified in 8.3.4. It is expressed as a value of prospective breaking current, in kA, or as a % of Icu (for example Ics = 25 % Icu). Ics shall be at least equal to 25 % of Icu.

Normally the Ics is smaller than the Icn.

EN 60898-1: 2020 – Circuit-breakers for overcurrent protection for household and similar installations

It only defines the Icn as nominal beaking capacity or nominal short-circuit power(Icn), or the value of the power of extreme short-circuit assigned to that switch by the constructor.

[IEC 60898-1:2020]: 5.2.4 Rated short-circuit capacity (Icn)

The rated short-circuit capacity of a circuit-breaker is the value of the ultimate short-circuit breaking capacity (see 3.5.5.1) assigned to that circuit-breaker by the manufacturer.

NOTE: A circuit-breaker having a given rated short-circuit capacity has a corresponding service short-circuit capacity (Ics).

The Icn, as the IEC 60898 says, need to have some requirements of sequence similar to that of the Icu described in the IEC 60947-2 but, despite this, it will have some differences.

[IEC 60898-2: 2021]9.12.11.4.3 Test at rated short-circuit capacity (Icn)

Replacement of the first paragraph:

a) The test circuit is calibrated according to 9.12.7.1 and 9.12.7.2, on alternating current with a power factor according to Table 17, or on direct current with a time constant according to 9.12.5.

Addition:

c) In the case of direct current, the test sequence for single- and two-pole circuit-breakers is:

O – t – CO

Two operations are made, the circuit being closed once by the auxiliary switch A and once by the circuit-breaker.

It exist a coefficient k given by the ratio between the Ics and the Icn, wich varies in function of the Icn considered; like what is shown in the schedule. It is important to know that even the switch complies with the EN 60947-2, on it, it will be written in the foreground , in a rectangle, the value of the Icn following the EN 60898-1

Example

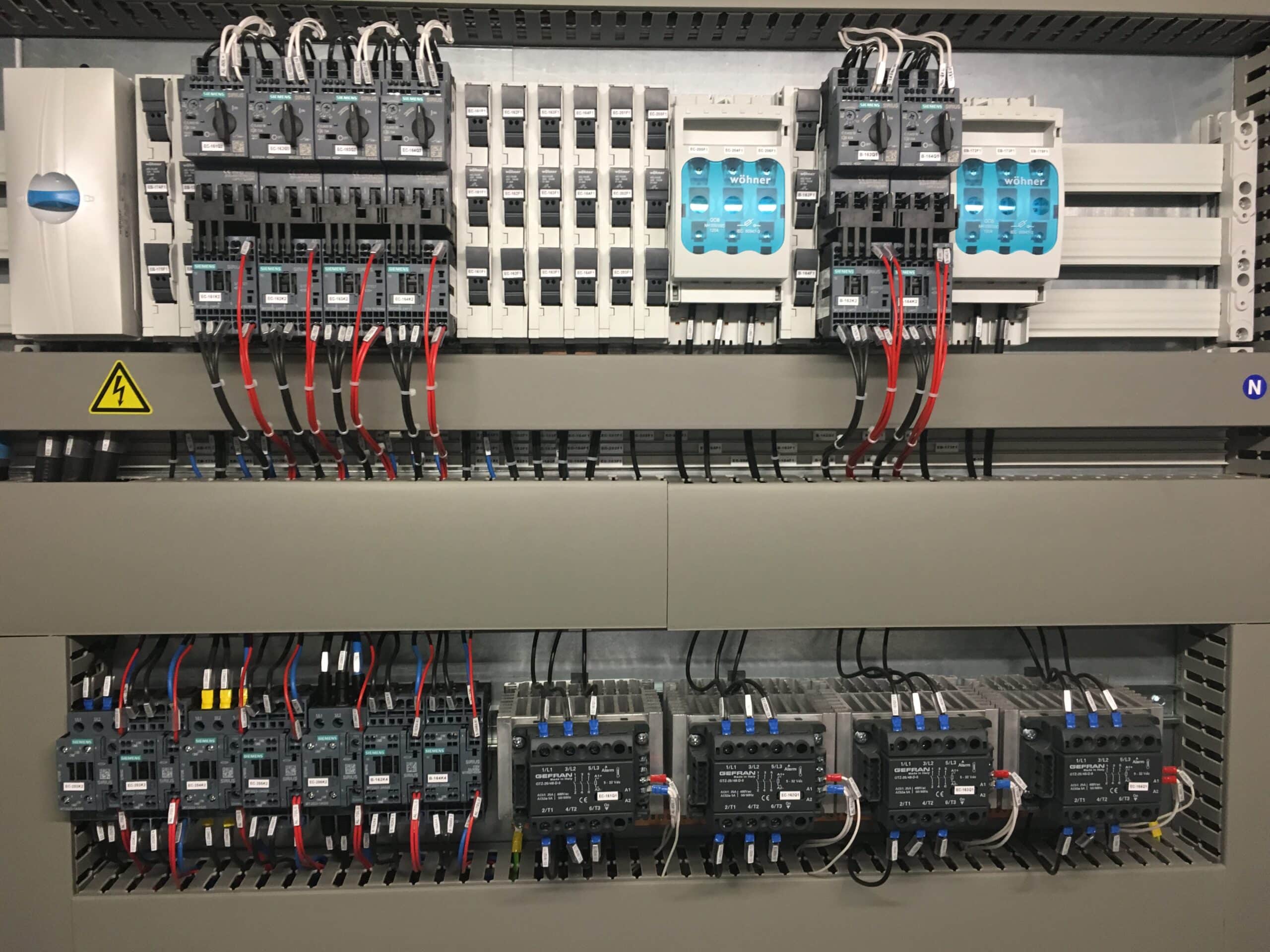

Here in the picture we can see an example of a magnetotermical protective device made by bticino, by being more precise the G23AC32 model. On it, if we observe in the low left corner, we will see it’s breaking capacity reported, wich indicates, like we see from the referential schedule, the value of the Icn that applies with the IEC 60898-1, in an electrical circuit in wich is present alternated current at the web frequency of 50/60HZ, differentiating the various monophase or triplephase sistems.

Like we see, the value of the breaking capacity Icn is going to varie in function of the nominal Vn and the number of poles.

In the example reported in the picture it is indicated the value of the breaking capacity for an alternate current circuit with a web frequency between 50 and 60 HZ with a nominal tension of 400 Vn in a triplephase sistem.

In the schedule, it will be reported the value of the Ics, wich correspond as the 75% of the Icn. Meanwhile, in appliance to the IEC 60947-2, the value of the Icu and the Ics will be indicated.

Conclusion

The breaking capacity of an electrical protection is the maximum current that this device can interrupt.

Two are the standards of reference, one is for switch used for civil area of use, and the second one is for those used in industrial area of use.

For each protection, the breaking capacity for the industrial standard is in general bigger than the one according with the civil standard. If a protection is alligned only with the product standard of the IEC 60898-1, it can also be used in industrial installations. But not viceversa.

For what regards the machinery, the constructor of the electrical equipment, for the calculation of the SCCR, can refer to the Icu following the IEC 60947-2