Last edit: 25/04/2024

THE DOUBT: What is the difference between Bonding, Earthing and Grounding? Is the motor frame grounded or bonded?

Why the Protective Earth (PE) conductor is called Equipment Grounding Conductor (EGC) in USA?

Those are excellent questions that we try to answer.

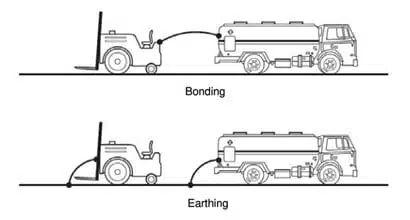

CONSIDERATION 1: Earthing and Grounding are synonyms and they mean to connect a metal part to earth, meaning to the “dirty ground”.

As an example, in a TN or TT system, the neutral point of a MV/LV transformer is grounded (earthed). In the drawing an example of a TN system: the resistance RN is the Neutral Resistance and you can see that neutral point of the transformer is earthed.

The term “Grounding” is used in USA and Canada; “Earthing” is used in the United Kingdom, Australia and, in general, all over the world. It is also the preferred term in the IEC 60364 series, but again, the meaning is exactly the same.

[IEC 60364-5-54: 2021] 541.3 Terms and definitions

541.3.8Earthing Conductor.Conductor which provides a conductive path, or part of the conductive path, between a given point in a system or in an installation or in equipment and an earth-electrode network.541.3.9 Main Earthing Terminal (main earthing busbar). Terminal or busbar which is part of the earthing arrangement of an installation and enabling the electrical connection of a number of conductors for earthing purposes

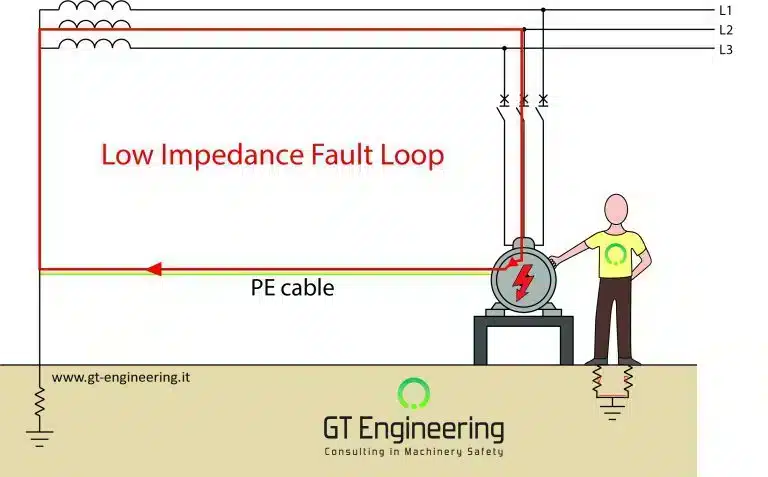

CONSIDERATION 2: Bonding is used in electrical safety standards all over the world and it means to connect two metallic parts with a PE cable. The primary objective of a Protective Bonding is to create the low impedance fault loop.

[IEC 60204-1:2016] 3 Terms, definitions and abbreviated terms

3.1.49 Protective Bonding. Equipotential bonding for protection against electric shock

Note 1 to entry: Measures for protection against electric shock can also reduce the risk of burns or fire.

Note 2 to entry: Protective bonding can be achieved with protective conductors and protective bonding conductors and by conductive joining of conductive parts of the machine and its electrical equipment.

Instead, the purpose of an Equipotential Bonding is to bring two metal parts at the same potential. For example, an Exposed and an Extraneous conductive parts.

[IEC 60204-1:2016] 3 Terms, definitions and abbreviated terms

3.1.26 Equipotential Bonding. Provision of electric connections between conductive parts, intended to achieve equipotentiality

CONSIDERATION 3: The subject seems very straighforward. In reality it is not and the reason is that important Technical Standards are not clear in their language. We take the example of the NEC (or NFPA 70). Hereafter is the definition of Equipment Grounding Conductor

[NFPA 70: 2023] Grounding Conductor, Equipment (EGC). (Equipment Grounding Conductor)

Informational Note No. 1: It is recognized that the equipment grounding conductor also performs bonding.

[NFPA 70: 2023]: Bonding Conductor (Bonding Jumper). A conductor that ensures the required electrical conductivity between metal parto; that arc required to be electrically connected. (CMP-5)

[CE Code: 2024] Bonding conductor — a conductor that connects the non-current-carrying parts of electrical equipment, raceways, or enclosures to the service equipment or system grounding conductor.

[NFPA 70: 2023] Grounded Conductor. A system or circuit conductor that is intentionally grounded. (CMP-5)Informational Note: Although an equipment grounding conductor is grounded, it is not considered a grounded conductor.

CONCLUSIONS:

Grounding and Earthing are synonym and they mean the connection of a metal part to ground (the dirty ground). A Lightning protection System (LPS) has to be earthed (or Grounded in USA and Canada) in order to disperse the lightning current safely towards earth. An electrical system is earthed (grounded) to create a TN installation.

Bonding is the connection of two metal parts with a PE cable (EGC in USA). The motor frame has to be bonded in order to create a low impedance fault loop path (TN systems).

In USA, the Equipment Grounding Conductor should be re-named Equipment Bonding Conductor: that will improve the understanding of Bonding and Grounding in the Code and among practitioners.