Last edit: 18/04/2023

Is an enclosure interlocking required for industrial control panels? That is a strongly debated topic and not yet fully understood: let's clear this out.

Requirement for an external Disconnecting Means

The confusion comes from the fact people combine two concepts:

– The possibility to de-energise the electrical panel without opening any door. That possibility is always required!

– The interlocking of all the doors so that the panel cannot be open unless it is de-energised. That requirement depends upon how the panel in internally built

The starting point is therefore the need to give the operator and/or the maintenance people the possibility to de-energise the machine from outside the electrical panel, without opening any door. This concept applies to control panels fed directly from the Industrial Premises. For downstream or secondary panels it's only a good practice to install disconnecting means, which can be inside the panel and without the external handle.

The possibility to de-energise the electrical panel without opening any door is a mandatory in IEC 60204-1, NFPA 79 and UL 508A, regardless how the panel is done internally. Most of the time that is done with an external handle.

Opening of the industrial control panel

Having clarified that, regarding the opening of electrical cabinets, EN 60204-1 distinguishes three different types of industrial control panels.

All three types require a main disconnecting switch with external handle, but not necessarily placed on the front door. They are:

- Industrial control panels that can be opened with a key (e.g. the disconnect switch can be placed on the side of the cabinet).

- Industrial control panels that must be de-energised to opened (e.g. single door cabinets with the disconnecting switch installed on the door and with the door interlock).

- Industrial control panels that do not need a key to be unlocked and opened.

Let's analyze the three types, one by one.

Type a)

Referring directly to EN 60204-1 Standard:

[IEC 60204-1]: 6.2.2 Protection by enclosures

[…] Opening an enclosure (i.e. opening doors, lids, covers, and the like) shall be possible only under one of the following conditions:

a) The use of a key or tool is necessary for access: all live parts, that are likely to be touched when resetting or adjusting devices intended for such operations while the equipment is still connected, shall be protected against direct contact to at least IP2X or IPXXB. Other live parts on the inside of doors shall be protected against direct contact to at least IP1X or IPXXA.

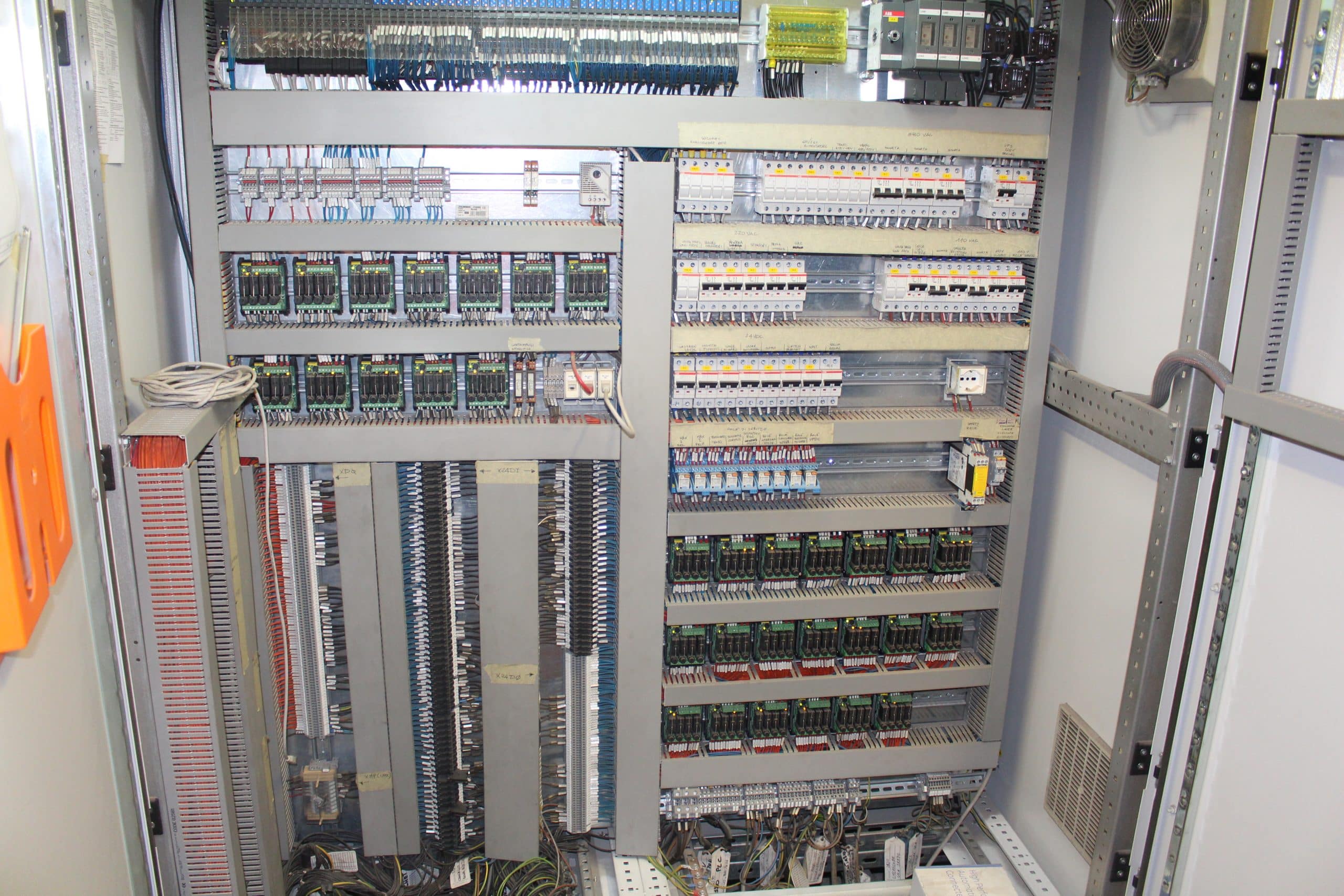

Basically, a type a) industrial control panel can be opened by using a key or other tools, without the requirement for a door interlock, provided that the degree of protection around live parts of components that can be frequently touched (circuit breakers, motor controllers, VSD programming parts, etc.) by operators and/or maintenance persons, is IPXXB, in order to guarantee protection from direct contact.

This means that the inside of an industrial control panel shall not be all IPXXB! Just the surroundings of the live parts that are frequently touched shall be IPXXB: in this situation the control panel can be opened using a key, still being energized and with the main disconnect switch in on position.

Type b)

Referring directly to EN 60204-1 Standard:

b) The disconnection of live parts inside the enclosure before the enclosure can be opened. This may be accomplished by interlocking the door with a disconnecting device (for example, the supply disconnecting device) so that the door can only be opened when the disconnecting device is open and so that the disconnecting device can only be closed when the door is closed.

If the requirement of IPXXB degree of protection for live parts that can frequently be touched is not met, then a door interlock must be installed to ensure that the live parts inside the control panel are de-energized before the door is opened. To avoid the risk of direct contact, the panel cannot be opened without first disconnecting the power supply. This means that de-energized live parts do not have to meet any degree of protection.

If, however, there are devices and/or parts that are still energized after the shut-down, then they must be protected with IPXXB degree and the cables supplying them must be orange.

EXCEPTION: If the door interlock can be bypassed using a "special" device or tool, the live parts frequently touched and maintained must be IP2X or IPXXB. Basically, this is the same situation as type a), since there is risk of direct contact in case of unprotected live parts and bypass of the door interlock.

Type c)

Referring directly to EN 60204-1 Standard:

c) Opening without the use of a key or a tool and without disconnection of live parts shall be possible only when all live parts are protected against direct contact to at least IP2X or IPXXB. Where barriers provide this protection, either they shall require a tool for their removal or all live parts protected by them shall be automatically disconnected when the barrier is removed.

In this case, the opening of the industrial control panel is subject neither to the use of keys or other tools nor to a disconnection. Therefore the requirement to be met to open the door is that the degree of protection of all live parts must be at least IP2X or IPXXB. Please note that the main disconnect switch (e.g. placed on the side) must still be installed to give the possibility to disconnect the voltage supply from outside the panel.

Is the door interlock needed?

"Type a)" Control Panels: all live parts "frequently touched during operation and/or maintenance" are IPXXB. However, there are live parts not correctly protected with an IPXXB degree in places where there are no devices such as circuit breakers or motor controllers: for example, the terminals of a transformer. Is a door interlock required?

Answer, NO it is not: the panel must have all doors that can be open with a key. There is no need to interlock the doors with the energy supply.

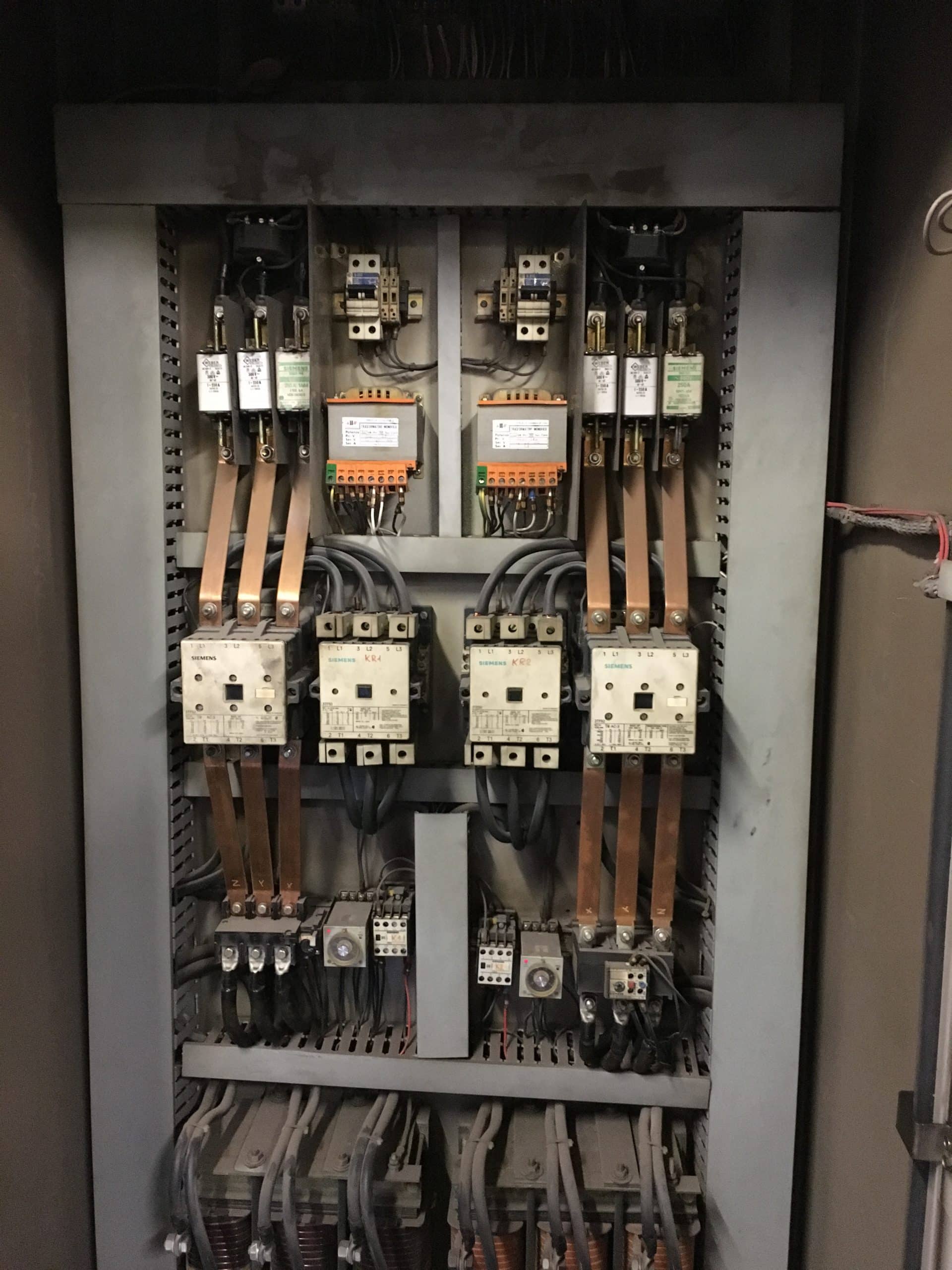

"Type b)" Control Panels: the inside of the control panel has many unprotected live parts and in particular the surroundings of the live parts that are frequently touched and maintained are not IPXXB.Is a door interlock required?

Answer: YES, it is. The control panel must be de-energised in order to be opened. The door interlock cannot be bypassed.

"Type c)" Control Panels: all live parts are IPXXB. Is a door interlock required?

Answer: NO, it is not. But please remember that the external handle is still required!